—OUGE shows you how to use the transformer properly

Modern industrial enterprises widely use electricity as a source of energy, and the power generated by power plants often needs to be transmitted over long distances to reach the area of electricity consumption. When the transmitted power is constant, the higher the transmitted voltage, the smaller the required current. Higher transmission voltage can be used to obtain lower line voltage drop and line loss, but it is difficult to produce a generator with high voltage, so it is necessary to use special equipment to increase the voltage at the generator before transmission out, such special equipment which is called electrical transformer. Today, OUGE will show you how to use the transformer properly for more durable.

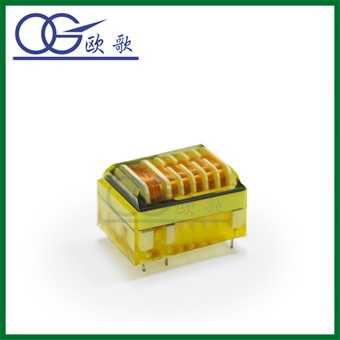

(OUGE Electrical Transformer)

Correct Usage

- Before use, please read the operation manual of transformer and the supporting control box in detail. Connect the connecting wire according to the instruction. The grounding wire should be well grounded.

- The power supply of the dry-type transformer control box is AC 220V and 380V respectively, and the voltage regulator outputs them to the low-voltage side of the transformer. It can be continuously adjusted to rated voltage through variable ratio output.

- When the DC withstand voltage or leakage current test is carried out, the high-voltage silicon reactor and micro ammeter can be firstly installed on the high-voltage output of the high-voltage test transformer, and then the voltage can be gradually increased to carry out the DC test.

(OUGE Power Transformer)

9 Tips on Usage

- Prevent transformer overload operation. If it is overload for a long time, it will cause coil heating and gradually aging insulation, resulting in short circuit between boxes, short circuit between phases or short circuit on the ground and decomposition of oil.

- Ensure the quality of insulating oil. If the oil quality is poor, impurities and excessive moisture will reduce the insulation strength. When the insulation strength is reduced to a certain value, the transformer will short-circuit and cause spark, arc or dangerous temperature. Therefore, the quality of the oil should be regularly tested and the unqualified oil should be replaced in time.

- Prevent transformer core insulation aging damage. Aging insulation of iron core or damage of clamping bolt bushing will cause great eddy current and long-term heating of iron core and aging insulation.

- To prevent the maintenance of insulation damage. When overhauling the lifting core of transformer, attention should be paid to protecting coil or insulating sleeve. If any damage is found, it should be dealt with in time.

- Ensure good contact of wires. Poor contact between the internal connections of the coils and the fulcrum points on the tap switch will result in local overheating, damaging the insulation and causing short circuit or disconnection. At this time, the generated high temperature arc will cause the insulation oil to decompose, produce a lot of gas, and add pressure in the transformer. When the pressure exceeds the set value of the gas cut-off protection without tripping, an explosion will occur.

(OUGE Power Transformer)

- Prevent electric shock. The power supply of power transformers usually comes from overhead lines, which are easy to be struck by lightning and the transformers will be burnt down due to breakdown of insulation.

- Short circuit protection shall be reliable. In case of short circuit in transformer coil, the transformer will bear considerable short circuit current. If the protection system fails or the protection setting is too high, the transformer may be burnt. For this, must install reliable short – circuit protection device.

- Keep good grounding. For the low-voltage system with protective zero connection, the neutral point on the low-voltage side of the transformer shall be directly grounded. When the three-phase load is unbalanced, the zero line will have current. When this current is too large and the contact resistance is large, the ground will appear high temperature, igniting the combustible material around.

- Prevent over-temperature. The temperature change should be monitored when the transformer is running. If the transformer coil wire is A level of insulation and the insulator is given priority to with paper and cotton yarn, insulation life will reduce about 50% when temperature rise every 8 ℃. Therefore, when the transformer is running, it must keep good ventilation and cooling. Forced ventilation can be adopted to reduce the temperature rise of the transformer.

For more info, please visit: http://www.ougedianzi.com/